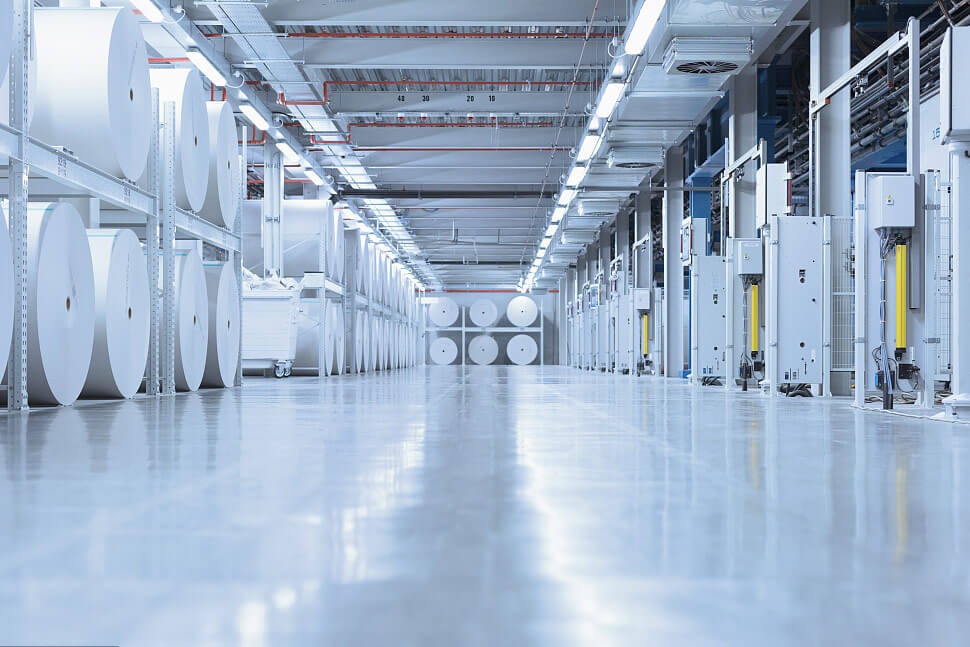

Pulp and Paper Making Application

Tetrasodium glutamate diacetate (GLDA-Na), trisodium methylglycine diacetate (MGDA-Na), tetrasodium aspartate diacetate (ASDA-Na), tetrasodium iminodisuccinate (IDS-Na) are environmental friendly chelating agents, green and degradable, are substitutes to EDTA and DTPA, can be widely used in hydrogen peroxide bleaching stabilizer, paper mill hydrogen peroxide stabilizer, various textile printing and dyeing papermaking auxiliaries, and fabric pretreatment such as desizing, scouring, bleaching and mercerizing etc.processes.

1. Pulp hydrogen peroxide (hydrogen peroxide) bleaching stabilizer

The special chelating agent for pulping has a strong ability to capture and disperse metal ions, can chelate with calcium, magnesium, zinc, iron and other multivalent metal ions in a wide pH range to form a more stable water-soluble complex. So as to prevent metal ions from reacting precipitation and scaling, ineffective & decomposition of bleaching agents, and yellowing of the pulp caused by metal ions during the bleaching process. At the same time, chelate has the effect of protecting pulp fiber and increasing dispersibility of bleaching solution.

Features

(1) Green degradable chelating agent can effectively inhibit the catalytic decomposition of hydrogen peroxide and hypochlorous acid bleaching agents caused by metal ions, improve bleaching efficiency, save bleaching liquid, and reduce bleaching costs.

(2) It has a strong ability to capture and disperse Fe3+ ions, to prevent Fe3+ ions from reacting with the phenol groups in pulp to form a dark-colored compound, protect the fiber, improve whiteness of pulp, and reduce the yellowing of pulp.

(3) It can effectively prevent metal ions such as calcium and magnesium from chemically reacting to form deposits during pulp bleaching process, thereby preventing scaling of system equipment and pipelines, and gradually removing the original scaling of the rinsing system.

(4) It has a certain dispersing ability and can improve dispersibility of sodium silicate.

(5) Protect the pulp fiber and prevent damage to fiber by NaOH peeling reaction.

(6) Compared with traditional DTPA, GLDA-Na/MGDA-Na/ASDA-Na/IDS-Na etc green degradable chelating agent has good environmental protection.

2. Cylinder sticking agent and patching agent for household paper machine, peeling agent for paper drying cylinder, and special improver for paper making

The creping process is usually used in production of household paper, which can make the paper soft. In creping process, the most important thing is to use a creping agent. The creping agent is mainly composed of two parts, the sticking agent and the release agent. Adding the cylinder sticking agent is a method to make the wet paper web reach the surface of the Yankee dryer and adhere to the surface of the dryer. In creping process, due to insufficient tackiness or rewetability of the adhesive cylinder, often lead to paper tearing, paper jamming, and uneven creping etc. phenomenons, and yellow edges are also produced on both sides of the dryer surface.

Used in crescent paper machines to produce cylinder sticking agent by soft tissue paper wrinkle control process. For conventional paper machines, it can show excellent cylinder sticking performance. Spraying on the Yankee dryer can provide excellent dryer protection basic coating and adhesion performance, which will help the paper sheet and the surface of dryer closely adhere, and the formation of soft coating will ensure the smoothness of the creping blade, avoid the accumulation of hard coating and the resulting vibration marks

Yuanlian Chemical specializes in the production of polyaspartic acid and tetrasodium iminodisuccinate, with stable quality and excellent quantity!

Contact us